At MKM Jewelry, one of the four primary metals we work with is sterling silver. It’s a popular metal all over the world for jewelry, art, electronics, and medicine. To learn more about silver, and how we use it at MKM Jewelry, read on for information about its origins and uses.

A Brief History

Silver was first mined as far back as 3000 B.C. in Anatolia (modern-day Turkey), and it was integral in the development of early civilizations in the Near East, Crete, and Greece. Around 1200 B.C., the majority of silver production shifted to the Laurium mines in Greece, continuing to help the empire grow. This later gave way to the dominance of Spain’s silver mines in 100 A.D., as they supplied a significant amount of silver to the Roman Empire, which was then traded along Asian spice routes.

A Drastic Change

Although silver was important in early trade, it was the discovery of the New World in 1492 that really made history for the element. The silver lodes in the Americas led to a drastic increase in mining and trade.

In Colonial America, silver was used for both currency and general goods. During this era, silversmiths knew all about working sterling silver, and they produced everything from belt buckles to ornate, artistic pieces. They used many of the methods for working silver that were developed in Europe, include sterling silver casting and cold working.

Essential Tableware

From 1840 to 1940, a fashionable dining room table in Europe or America was not complete without sterling silver flatware. For many colonials it was all about sterling silver pieces, and at the peak of their popularity, these silverware sets could contain up to 100 intricate pieces.

During World War II, a shortage of copper meant that silver saw a surge in industrial applications, and it was used in aircraft parts, electronics, reflectors, and soldering.

Mining Locations

After the Spanish conquest of the New World, silver mining flourished in the new colonies. From 1500 to 1800, Bolivia, Peru, and Mexico accounted for 85% of silver production and trade. After 1800, silver mining began to expand to other countries. In the United States, the discovery of the Cornstock Lode in Nevada allowed them to contribute significantly to the silver trade. By the 1870s, silver production had doubled from 40 to 80 million troy ounces worldwide.

Present Day Mining Operations

Present-day silver mining takes place mainly in Mexico, Peru, the United States, Canada, Poland, Chile, and Australia. In the United States, silver is mined in 16 different states, with Nevada, Idaho, and Arizona accounting for two-thirds of all silver mined in the country. Today, almost 671 million troy ounces are mined every year.

The price of silver is prone to fluctuation, rising when demand increases and dropping when silver deposits are discovered. Since most silver-rich ore has already been mined, most of today’s silver comes from ores with trace amounts of the metal. Through a process called electrolysis, these tiny amounts of silver are extracted.

Interesting Silver Facts

To learn all about sterling silver, we have to consider its properties outside of just sterling silver casting for jewelry. Silver is considered the best conductor of electricity and heat compared with any other element. Since it is the best reflector of visible light, silver is often used to make mirrors. It’s the most ductile and malleable metal, which means it can be formed into thin wires and hammered into thin sheets without breaking.

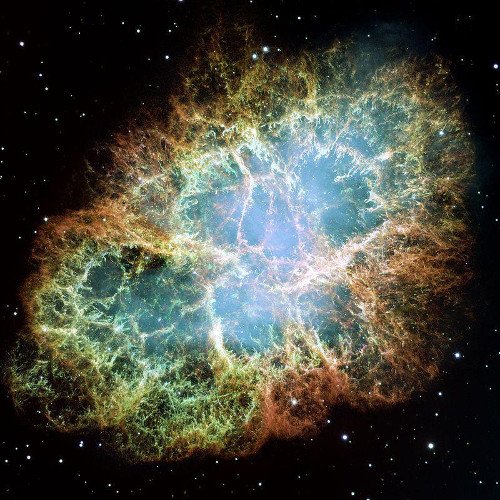

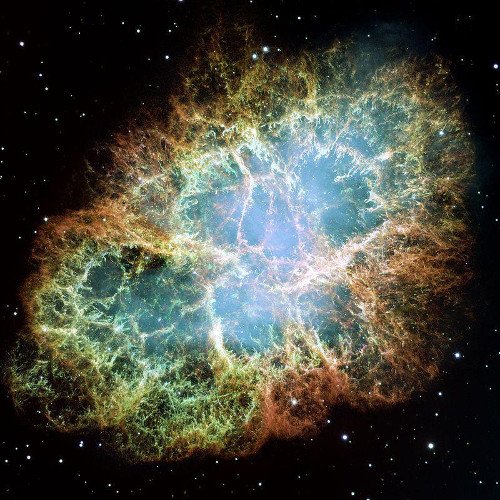

Like gold, silver forms from star explosions called supernovas. The explosion of smaller stars produce silver, while the explosion of larger stars creates gold.

Current Uses of Silver

While we may think all about sterling silver jewelry and silverware, silver actually has a variety of artistic, scientific, and medical uses.

In Photography

In 1871, Richard Leach Maddox invented a new, important use for silver in photography through the gelatin silver process. In the gelatin silver process, silver ions suspended in gelatin are used to coat photographic film. Exposure to light causes the silver ions to darken, and other developing agents, like photographic fixer and a water bath are used to produce the final result. Even with the widespread use of today’s digital camera, silver remains integral to artists working with traditional film.

In Power

Silver is used to manufacture solar photovoltaic panels, which are used to collect solar energy. Plasmonic solar cells, which convert light into electricity, are also made using silver. Since silver is the most reflective element, scientists have used large curved sheets of the metal to create concentrated solar power collectors. By 2015, 100 million ounces of silver had been used for solar energy purposes.

In Electronics

Due to its superior electrical conductivity, silver is commonly used in electronics. It’s used in printed circuit boards that are central to everything from mobile phones to computers. Silver-based inks and films are applied to composite boards to create electrical pathways, and silver-based inks produce RFID (radio frequency identification) tags that are used to both prevent theft and make inventory control easy.

In Medicine

Perhaps one of the most surprising uses for silver is its applications in medicine. Silver has antibacterial properties, and it has been used in wound dressings since World War I. Today, burn patients benefit from silver-antibiotic creams and silver wound dressings to help prevent infection and promote healing. With the rise of the so-called superbug MRSA (Methicillin-resistant Staphylococcus aureus), hospitals have taken to using silver-embedded equipment to prevent the spread of the infection.

In Jewelry

Silver is, of course, also used to make jewelry and art. Throughout American history, the most notable producers of silver jewelry included the Native Americans of the Southwestern regions including the Zuni and Navajo tribes. At MKM Jewelry, we also create a multitude of silver pieces through sterling silver casting.

What Is Sterling Silver?

The idea that silver jewelry isn’t pure silver may be jarring at first, but learning all about sterling silver makes it clear that it’s the best material for the job.

In its pure form, silver is too soft for things like jewelry. In order to help it keep its shape and increase its hardness, silver is mixed with other materials to imbue it with more strength. Traditional sterling silver is made up of 92.5% silver and 7.5% of other metals, usually copper. Alternatives to copper include germanium, zinc, and platinum, and additional materials like silicon and boron are sometimes added. To denote sterling silver was used for a piece, the numbers 925 are often carved into the finished product.

Silver Finishes for Jewelry and Art

After silver is worked into shape for jewelry or art, it can be finished in different ways for a variety looks. At MKM Jewelry, we know all about sterling silver

finishes including matte, oxidized, highly polished, stone finished, brushed, and raw.

A Matte Finish

A matte finish diffuses light for a subtle sheen. With matte finishes, there are several textures that can be achieved such as stone finished and brushed. For a brushed matte finish, a small, lined tool dulls the surface of the silver, leaving small patterned lines. For more texture, a stone finish offers a more rugged finish reminiscent of actual rocks.

An Oxidized Finish

To provide an oxidized finish, sterling silver is deliberately exposed to air that contains sulfur. The resulting silver sulfide compound creates blackened patches for an aged, vintage look — like those often found in Native American pieces.

A Highly Polished Finish

A highly-polished mirror finish takes the most work to achieve. To make the jewelry reflect light in a dazzling way, the silver is worked until all imperfections are removed. The silver is then polished until it has a bright, shiny finish.

A Raw Finish

For a raw finish, the metal is cleaned and pickled, but the skin remains intact. This results in a dull outer layer that does not reflect much light. Many artists who wish to convey a masculine feeling in their jewelry choose this style.

MKM Jewelry and Silver

At MKM Jewelry, we have learned all about using sterling silver in a multitude of different jewelry-making techniques. We use the metal primarily in lost wax casting, plating, and engraving.

Sterling Silver Casting

Lost wax casting is a type of casting whereby molten silver is poured into a mold. The mold is created using wax, which is then melted and drained out. Lost wax casting has been around for thousands of years, and there are different methods of wax casting depending on the type of metal used. For a soft metal like sterling silver, the material is cast at a relatively low temperature (1500-2000° F). At MKM Jewelry, we use a gypsum-bonded investment for this process.

Engraving

We offer two types of

engraving: laser engraving and hand engraving. If you want a design that requires a lot of precision, or you want an engraving consistent on many pieces of jewelry, that’s what laser engraving is all about. Sterling silver jewelry can be laser engraved using the precision of the computer for sharp, smooth lines. This type of engraving is perfect for specific fonts, blackening techniques, and even images.

Hand engraving may be a more favorable option if you’re seeking to engrave just one or a few pieces of jewelry. Our skilled artisans know all about engraving sterling silver jewelry with masterful technique and a quick turnaround time. Hand engraving is an excellent way to add character to your existing pieces of jewelry.

Plating

If you’re not all about sterling silver’s color, we offer plating services after the jewelry is made. Plating is available in gold, rose gold/silver, and rhodium. With plating, we can work with sterling silver as the base metal and then add a unique, customized touch at the end.

Working with the Best

The professionals at MKM Jewelry have over 15 years of experience working with sterling silver. All our knowledge about sterling silver means that we’re equipped to help you create the piece you’ve been imagining. Whether it’s a one-of-a-kind piece or a run of over a thousand, let MKM Jewelry help you make your jewelry come to life.

Leave a Comment